Native starch finds its way to the food and nonfood industry either or not after modification.

Heating moist starch produces a sticky gel that is used as an adhesive for wall paper and gummed tape. When added to paper pulp, it strengthens the paper and makes it suitable for use in paper sacks. Potato starch is used to stiffen cloth. It also reduces the porosity of paper and its adjusted absorption capacity for ink and colorants, provides a smoother surface and reduces the amount of ink needed for printing. Specific surface applications make paper glossy as desired for magazines. Waxy starch (amylopectine only) replaces synthetic polymers to ease the weaving of cotton threads. The drilling industry for oil exploration uses potato starch because it alters the viscosity of the drilling fluid, thereby lubricating the drill head. It also keeps the ground rock in suspension and improves its transfer away from the drill head. Potato starch and fibers are fermented with lactic acid bacteria to produce lactic acid (CH3CH(OH)CO2H), which, through polymerization, forms polylactic acid (PLA), a transparent petrochemical-based polyethylene. This bioplastic, like glucose- and starch-based bioplastics, is biodegradable. When reinforced with bio-based fiber such as hemp of flax, it produces material for industrial use such as for the automobile industry.

Application of potato starch in color photography

A now obsolete use of a very limited negligible amount of potato starch was its application in color photography developed by Auguste and Louis Lumière around the turn of the last century: the Lumière Autochrome. Potato starch grains were divided into smaller and larger grains, the latter are heavier, precipitate faster in water and were discarded. The small starch grains were colored with the complementary colors orange, green and violet with synthetic colorants. A random mixture of the grains was sprayed and one layer thick was fixed on a sticky varnished glass plate, over half a million grains per square cm. The small voids between the grains were filled with carbon powder. The result was rolled flat, fixed with varnish and covered with a light sensitive emulsion that consisted of a gel containing silver bromide. When making a photograph, the glass plates were placed in the camera with the starch grains towards the lens. The grains filtered the light and cast a negative image. On reversing the plate and exposing it to light again, a positive image appears in true colors. The process was one of the common methods of color photography in the early 20th century, but it was replaced by red-green-blue techniques of Agfa and Kodak in the mid-1930s.

Photo: Enlargement of colored potato starch grains for Lumière autochrome color photography (wiki).

Biorefinery of potato. In a starch factory, the three basic products that are made are: starch, protein and fiber. Originally, protein energy production was coagulated by heating the fruit juice and used as feed. Fiber among other uses also was applied as animal feed producing energy (methane) and starch was used for industrial purposes. Current potato starch industry increasingly becomes a food industry applying biorefinery with a cascade of products. Reconstituted fiber, protein and starch produce doughs for crisps, chips and extruded products. New native (e.g. amylopectin only) starches are modified into hundreds of novel products. They are e.g. enzymatically hydrolyzed or oxidized into specific lengths, or mechanically extruded into specific configurations. Lifecycle analysis favors many applications of potato starch and protein over such starches as from corn no neutral taste and protein from soya (less soluble and less versatile).

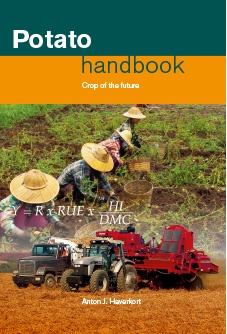

Want to keep reading about the potato crop and potato starch production and modification?

Our Potato handbook is a global potato university in 1 book!

Buy your copy today and get a one-year free subscription to PotatoWorld magazine.