Washing of tubers to remove adhering dust, soil and clay caps usually takes place in the processing factory prior to peeling. Moreover, packers generally wash the tubers and subsequently dry them before they are packed in supermarket ready wrapping.

Washing on the farm when not packed there, does take place just prior to delivery if the buyer, usually a crisp factory, so desires. Some processors only accept graded, washed and sorted (blemished removed) tubers and pay a premium, a higher price than for a crop that leaves the field without any operation.

Advantages of washing

The advantages for the processor are obvious - less transport, less tare and less waste to handle. The grower when washing in the farm returns the waste water to the field and uses or sells the rejects as feed. Fries plants usually buy the crops as they leave the field because they can make any product from almost all tubers. Their factories are located near the potato growing area whereas crisps factories are located far away near population centers.

Weighing, packing and palletizing potatoes

In subsistence potato production systems in the Andes, Africa and parts of Asia where only part of the crop is sold for cash, this is usually done without washing, weighing and packing. At markets potatoes are not packed but piled per quantity established by a large tin or bucket or displayed in bulk and weighed when selling on the spot. Traders come to the countryside and buy potatoes by weight or by the bag. When prices are low the jute or nylon bags are enlarged by weaving an extension. The bags are transported to the wholesale market in the capital or other major cities where they are bought, bag by bag, by retailers who make small piles of tubers of different size and color and price them according to market supply and demand. Besides a basket or a large reused tin serves as a measure of a fixed quantity accepted by the local consumer community.

At packing stations, after cleaning, potatoes are graded and optically sorted, packed (2) and palletized (3) or placed in containers (4) before being transported to outlets as diverse as supermarkets, catering companies and cruise ships.

Want to keep reading about the potato crop and the washing, weighing, packing and palletizing of potatoes?

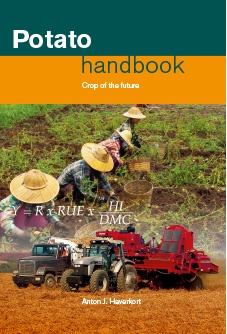

Our Potato handbook is a global potato university in 1 book!

Buy your copy today and get a one-year free subscription to PotatoWorld magazine.